Page 550 (From INDEX OF WITNESSES which gives pages where

witness testimony is found.)

Taylor,

Charles, engineer (Bridgewater), Madoc, Oct. 2.

................................ .52, 86, 111, 133

(He is

also in effect mentioned on pages 79 & 87)

page 52

Charles Taylor—We get actinolite within

a distance of two and a half to four miles from Bridgewater; there is some in

the 2nd concession of Hungerford, and Hungerford and there is some on lot 7 in

the 2nd concession of Elzevir. I know where there is plenty of it, but the

greatest deposits are in those places; it is in pockets in a magnesian rock

associated with dolomite. It appears in forms like veins, which run crosswise

of the country rock. We find it at the

surface, but have never been successful in following it to any depth; it

appears to be in pockets and runs out.

Page 79

ROOFING MATERIALS. [Not C.H. Taylor’s words.]

Fibrous serpentine, called

"actinolite," is found near Bridgewater, in the county of Hastings.

No member of the Commission visited the places of production, but the process

of manufacture at the mill in Bridgewater was witnessed. This consists simply in breaking the rock in a Blake crusher and

then grinding the crushed material in Taylor's disintegrator, after which it is

bagged and shipped. The rock is similar to what is called fibrous talc in New

York state, where it is ground for a like purpose.[disintegrator = pulveriser mentioned on page 86]

Page 86

Charles Taylor—My business is that of

engineer. At present I live at Bridge-water, Ontario. For the last twenty-five

years I have been interested in mining in Nova Scotia and Ontario. In Nova

Scotia I was employed by the London Gold Mining Co. as superintendent of their

works, and I erected the first crusher in that part of the country. I came to

this part of Ontario about six years ago from Montreal. Directly or indirectly

I have been engaged in mining operations for about twenty-five years. I have

been working the actinolite mills at Bridgewater. I put up the works there, and

I have three patents on the process, one for breaking the stone, one for

pulverising, and the other for a composition for roofing. The actinolite occurs

diagonally in the vein, at an angle of about 40 degrees. We get it sometimes in

veins, sometimes in pockets; some of the pockets are from 10 to 12 feet broad,

and where found in pockets it is generally in prisms. It seems to be associated

in an upheaval between the dolomite and the gneiss or trap. On the east side is

a conglomerate of limestone and quartz pebbles, with a matrix of limestone;

next the conglomerate is slate then magnesian rock, and then the gneiss again.

There is no trap near the actinolite itself. I have seen actinolite occurrences

in other parts of the country, but only on the same range of rocks; I have not

seen them in any other range. This is the only place I have seen it in Ontario. I have seen it in the province of Quebec; but

there it does not occur in the same manner, being associated with asbestos. We

get different kinds of actinolite; one kind is long, another comes up in prisms

from one-half or five-eighths of an inch to six inches long. It is all the same

when ground. We have not found any asbestos. I think the present source of

supply may become exhausted without regular mining and a great deal of expense. During the six years I have been in the

business we have sent away from our place about $6,000 worth a year. The

actinolite is first broken up, then it is pulverised, then it is ground into

dust, except that the live fiber is drawn the same as paper pulp; that absorbs

the tar and it consolidates. We mix it up with tar the same as mortar, and it

can be put on the same as mortar. What we ship from the factory we do not mix

with tar; we sell it in a pulverised state. It is put up in bags containing;

100 pounds; one bag contains enough for10 feet square of roofing and the price

per bag is75cents. It takes about 30 horse-power to drive the machinery for

grinding 25 to 30 tons a day. We use water power altogether. Our mill runs about six or eight weeks in

the year, and we find a market for our product in Canada and the States. We

always have orders ahead, and this year we could not fill all the orders

because we had not sufficient water. In addition to roofing our product is used

for sidewalks and the foundations of houses. It does not crack or shrink, and

it is fire proof. The tar will burn a little, but that forms as a crust; it is

a non-conductor. At our mills we employ sometimes as many as 16 or 17 teams.

Five men are employed in the mill, and at other times the same men work in the

mine. We pay $1.25 a day to men, and

$2.50 for teams. The duty entering the States is 10 per cent, because it is not

a finished article; that amounts to about $1.50 a ton. The raw material costs us about $3 a ton.

Page 87

Joseph James—I am in partnership with

Mr. Taylor in the actinolite business, which is now in liquidation. The capital invested is about $17,000 or

$18,000. Mr. Taylor's share is about $3,000. The cement we manufacture is made

for roofing. It is altogether different from any other kind of cement; it is

the only one using actinolite or fiber to make the bond; the others use mica

for that purpose. We also grind cement in which mica is used as a further bond,

and I think this is an improvement. As the trade get it, it is ground to about

60-mesh; it is mixed with coal tar and pitch, and sometimes asphalt, according

to the quality of the roofing desired. It is spread on the roof while hot, the

total thickness including the felt on which it is spread being half an inch.

This, roofing never gets hard; it remains elastic, and will bend to a limited

extent without cracking. Our patent covers the use of actinolite with coal tar

or its chemical equivalent. The process of laying it is not a patent, only the

materials. The cost is about the same as a good gravel roof, and it is more

durable and better in every respect. The

coal tar or pitch is hermetically sealed in the material, and cannot possibly

evaporate or dry up. The sun or the frost will not affect it. It is as

fireproof as a roof can be; more so than any metal roof. Insurance companies take it as a first class roof. It has another

advantage over metal roofs besides being much less expensive; it is not

affected by coal gas in cities, as is the case with metal roofs, particularly

in foggy weather. The proportion in mixing is 11 gallons of coal tar or its

equivalent to 100 pounds of actinolite. It is infusible; it can be softened by

heat, but cannot burn. I grind some mica for the Grand Trunk to use as a

lubricator. The first cement was made here in June,1883, since that time there

has been turned out about 50,000 bags of 100 Ib. each. Last year was our

smallest year's business, owing to trouble among ourselves. It is now four

years since any endeavor was made to extend the business, but I think it is

capable of being extended largely. Our principal markets are Montreal, Chicago

and Detroit. I am satisfied with Taylor's pulveriser; l don't know of anything

to beat it. I can put through 25 tons a day of ordinary rock, 12 hours work and

2,300 revolutions to the minute. It will grind 20 tons of phosphate in ten

hours. Working easily it will do about 11/2 tons of the actinolite an hour. I would

recommend it as the best grinder l know. I have seen it grinding bones in the

Montreal abattoir. It will do about the same amount of quartz as of phosphate.

The vein on lot 7 in the 1st concession of Kaladar is 10 or 12 inches wide on

the surface. We have gone down 23 feet, and it is about from 21/2 to 4

feet wide. I think it is a vein there, because I never found it in any place

else to that depth. Our material costs us from $1 to $5 a ton.

page 111.

“Charles Taylor.— We are at present

taking the gold out of the tailings of the Consolidated mine by amalgamation.

Our process is a simple one and is not patented ; it simply consists in using a

sodium amalgam. When our mercury flowers we use a copper amalgam. I do not

think we get all the gold. In every ton we put through I think we leave $35 or

$30; if assayed it will show that. By the first process the company adopted I

do not think they got more than $7 or $8 a ton of concentrates, though it

assayed from $60 to $70 to the ton. The first process was to pass it through

Cornish rolls, then it went through a large screen, then Extracting ore

condensed in a large chamber. The average gold in the ore was $15 to the ton,

and in the concentrates $80 to $80, but it is seldom that more than one-half

the amount of the assay is got. We take about $4.50 a ton out of the tailings;

we put through about eight tons a day, and with two men we take out from $100

to $!50 a week. We began working about the latter part of June, but water was

scarce; now water is plenty, but the weather is getting too cold. This ore was

treated by the chlorination process, but the article treated was not half

burned, and all the gold was got out of the small part that was calcined. The

dust on the beams of the wall assays $20 to the ton. The oxide of iron, if

outside the gold, prevents the mercury from touching it, but by using caustic

soda the oxide of iron is cut from the surface. In a building 40 feet square I

can do twice as much as they can do with all their works at Deloro, which cover

half an acre. My pulveriser can be placed in position with out foundation or

anything of that kind. After crushing the ore I would burn it and take out the

arsenic, and then it would be in a state to take out the gold by my process. If

you were to stamp as fine as my pulveriser does you would not be able to do

more than a ton a day, while I can pulverise from 8 to 10 tons a day. This

machine occupies but a small space, and I am prepared to enter into a contract

to crush from 8 to 12 tons a day, and put it through 60 mesh. These refractory

ores; should be calcined in all cases. I have not as yet treated any arsenical

ore here that was not treated before, but we treated arsenical ore in Nova

Scotia. Except my process, I do not know of any by which it can be successfully

treated; no one has treated it with caustic soda but myself. The proportion of

caustic soda used is about two pounds to the ton of water. We keep the water up

to blood heat and oxidise the mercury with acids; we also use a little muriatic

acid and a little sulphur sometimes. The caustic soda will clear grease from

the mercury.”

Page 133

Charles Taylor—Sometimes we get very

good shows of copper and iron pyrites in the actinolite district. There is a

large bed of iron pyrites in Hungerford, south of Copper and the Sheffield

station. It is from four to six feet wide, and I think it extends over a large

area. A pit has been sunk down 30 or 40 feet, and it can be shovelled out. A

gold crusher was built upon it once, but there is only a show of gold.

Page 478 [The Taylor kiln mentioned below likely has nothing to do with C.H.

Taylor, but he mentions burning the ore on page 111. That burning likely

involved a kiln.]

The Swedish Westman kiln and Dillner kiln

divide with the American Taylor kiln the commendations of Mr. Lilienberg, an

authority on the subject. The last named is the least expensive kiln, and its

capacity for reducing the sulphur in the very sulphurous magnetic ores of New

Jersey has been successfully demonstrated. Whether the like result is

attainable with less sulphurous ores such as those of eastern Ontario is not to

be inferred without trial. The facility with which any ore will part with

sulphur depends upon its density, crystalline texture and the mineral character

of the pyrites. Summing up the requirements of a roasting kiln, they seem to be

as follows: (1) The sulphur shall be reduced by single roasting from 3 to 4

down to 0.10 per cent. (2) Fine ore and lumps have to be roasted together as

they come from the mines, without any extra expense for separation. (3) The

cost of a kiln roasting 50 tons of ore a day shall not exceed |2,000, which of

course ought to stand in some proportion to the price of the ore. (4) The cost

of roasting shall not exceed 25 cents a ton. (5) The height shall not be

greater than the space below the track in the stock-house, or about 12 feet, in

order that elevators may be avoided and hopper cars used for direct

unloading."^ Such are the tests to be applied in estimating the qualities

of a kiln, in the opinion of Mr. ….

* In the Taylor kiln with its short space

above and the long space below the gas inlet* sulphur is generally reduced from

2 to 5 per cent, down to 0.25 per cent., sometimes to 0.10 per cent. The cost

of erection is $l,800 to $2,000, or about one-fourth of that of the West man

kiln. The height for lifting the ore is about the same. The consumption of coal, which is an important item where the

waste gases from the blast furnace cannot be used, is reported to me so

low as l cwt. lump anthracite per ton of ore.—Journal of the Charcoal Iron

Workers, vol. ni5p. 264.

f N. Lilienberg, in the Charcoal Iron

Workers' Journal, vol. in, pp. 261-263. J Journal of the Charcoal Iron Workers,

vol. in., p. 265,

============//===========

CULTURAL HERITAGE EVALUATION REPORT DELORO MINE SITE, COUNTY OF HASTINGS

6.5 After Canada

Consolidated

The story of Canada Consolidated runs cold

after 1883. It is assumed that the corporate entity continued to exist and own

the land. From then until 1896, the property was worked intermittently by two

operations which exploited the heavy capital investment made by Canada

Consolidated.

6.5.1 Charles Taylor

In June 1888

Charles Taylor, a local mining engineer, started extracting gold from the mill

tailings. He used a simple amalgamation process and obtained about $4.50 of

gold per ton of tailings. Working with two men he extracted about $100.00 to

$150.00 per week. Taylor boasted that he used a building 40 feet (12m) square

and could process twice as much ore as the original company could do with a

mill that covered half an acre. However, he did admit that he was treating

arsenical ore that had already been concentrated by the previous company.133

APPENDIX D Maltby and Associates Inc

Collections Report

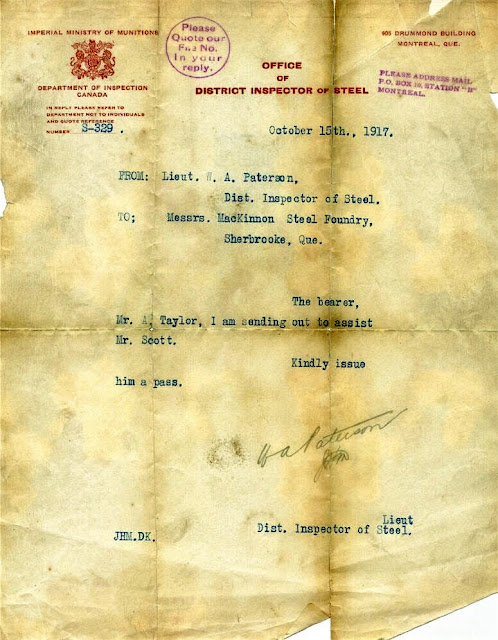

Charles Taylor: In 1888 a Mining Engineer by the name of

Charles Taylor was extracting gold from the tailings of the Consolidated Gold

Mine. Taylor had been in the mining business for 25 years and worked in Nova

Scotia and Ontario. He came to Ontario about 1882 and was living in Bridgewater.

He was involved in a number of mining activities.