Dept. of Mechanical Engineering,

University of Toronto,

Oct. 31, 1951

Roy is a member of Charles Taylor's second family. He acquired his Engineering degree and worked in the family business with his father Charles H. Taylor Sr. and his older brother Charles (Bud) H. Taylor until they closed down the business. Roy has since retired but has remained both active and creative.

History:

It may be of interest to the reader to know at least a brief history concerning the developmentof this compressor, therefore at this point I will present a review of the major events that led to its first successful application.

One of the earliest forms of compressed air devices had its origin in the early years of the iron age and was known as the trompe or hydraulic air blast for forges. Its purpose was to supply the Catalan forges with a steady blast of air. The preassure produced in this type of compressor were of a very small magnitude being in the neighborhood of one ounce (1 oz.) to one pound per square inch (1 lb./sq. in.) The best type of construction in trompe mechanism was one wherein the range of the apparatus could be produced by means of a sliding gate. The operation of the apparatus may be explained by referring to figure 1. Water falling into the tube draws air through the small inclined holes, indicated by arrows, and carries this air down into the reservoir where the air separates from the water and escapes to the forge. The outlet column is high enough to balance the pressure maintained in the reservoir.

In the year 1877, Mr. J.P. Frizell carried out tests

of a practical scale on this system utilizing a 5 ft. fall and a 36 ft. shaft at the falls of St. Anthony near St. Paul on the Mississippi River. From his tests he proposed a system known as the Frizell system, see figure 2., for which he secured patents. Later compressors were somewhat similar to this system but the actual design involved was quite different in certain respects.

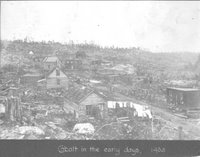

The next major step was made by Mr. C. H. Taylor in 1896 at Magog, Quebec where he erected the first working hydraulic air plant on a practicle scale. The Taylor plant, although essentially utilizing the method outlined by Frizell, was materially different in detail and proportioning of the various parts of the plant. It may be noted here that Mr. Taylor discovered the principle himself by noting how water flowing down the spillway of a dam carried a certain amount of air with it as it plunged under the surface of the river ice. This air carried downstream by the flowing water, released itselt from the water and formed large pockets of air under the ice. This caused the ice to bulge upwards and when he broke one of the pockets and discovered that air under pressure was trapped here he also discovered this principle that he put to much use. Thus independent and ignorant of any other proposed system, he erected at Magog the first plant for the purpose of supplying air to a cotton mill.

The air supply from this plant was ample for the needs of the mill and its success here led to its further application in the field of mining. The efficiency of the plant at Magog though relatively high was improved on by a better proportioning of the parts and the later plants had efficiencies of 82%, an improvement of 20% over the Magog plant. Three separate patents were obtained by Taylor for his design of the hydraulic air compressor in 1896, 1898 and 1900.

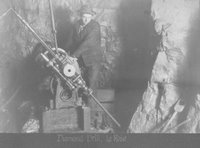

The plant at Ragged Chutes is 5500 H.P. with a 1000 H.P. reserve. A 660 foot weir dam was built across the Montreal River to control the water flow. The air is transported by means of a seamless steel pipe. These specially designed pipes were brought in from Germany. A total of 21 miles of pipe were required for the project.

The plant at Ragged Chutes is 5500 H.P. with a 1000 H.P. reserve. A 660 foot weir dam was built across the Montreal River to control the water flow. The air is transported by means of a seamless steel pipe. These specially designed pipes were brought in from Germany. A total of 21 miles of pipe were required for the project.